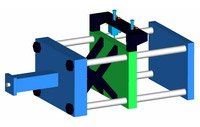

5 gallon PET blow moulding machine (MG-120)

Brief Introduction

MG-120 5 gallon PET blow moulding machine is used to produce 5gallon PET bottle that is now demanded extremely in the market. Facing great demand for 5 gallon PET bottle at market, MG-120 will certainly become the right machine for your investment. The whole procedure is automatic. It is controlled with microcomputer. In order to achieve the purpose of automatic transporting bottles, the user should connect the conveyor belt with the blow molding machine. By transmission device, the machine can be connected to the filling machine directly and start inline filling.

Overview

* Control system

The control system is the heart of MG-120

PET blow moulding machine. Together with

Hi-tech Man-Machine Interaction (MMI)

control panel with user-friendly, the whole

control system presents super performance

with precise control, convenient parameter

setup, obvious display and reasonable

memory.

* Pneumatic system

Pneumatic system provides the power for

MG-120’s movement. World famous high quality

pneumatic components equipped on MG-120 such

as Festo from Germany, specially designed

high-pressure valve, high precise action,

long service life and reliable performance

are their highlights. Network of those

pneumatic components suppliers’ global

service ensures customers their prompt

after-sale service locally for their

pneumatic products used on MG-120.

* Sensor system

MG-120 5 gallon PET moulding machine adopts

high quality imported sensor & switch

system including proximity switch,

photoelectric switch, and electronic magnet

switch to keep production process going step

by step and avoid any possible damage on

machine.

* Heating system

MG-120 automatic PET blow moulding machine

adopts infrared type heating mode, whose

superior thermal-radiation and thermal

penetrability provide machine with powerful

heating to meet strict preform heating

requirement under speedy moving. Number of

infrared heating lamps placed onto three

heating zone with 9 sets of independent

voltage adjusting module and advanced

microcomputer controller, can offer ideal

heating for preform of different sizes. Each

lamp’s horizontal position is adjustable to

keep the machine agile.

* Clamping system

MG-120 adopts three-plate type toggle

clamping unit. Apart from the three-plate

type toggle clamping unit, there is a high

pressure assistant clamping device that is

special designed to get a firm clamping.

* Preform feeding & bottle discharging

system

MG-120 automatic stretch blow molding machine is equipped

with special preform loading system, which protect the neck

of the perform from possible damage and allow to make a

slight change of preform dimension without changing prefrom

holder. The heated preforms are blown with neck up in order

to ensure the quality of the finished bottle, and then

shaped bottles will automatic fall down during the machine’

movement.

Features

1. Special Feeding system carries the preform

automatically.

2. Suit to produce 5-25L wide mouth PET container

3. Advanced PLC control system with a use-friendly control

panel

4. Reliable sensor system monitor machine’s auto

running

5. Powerful heating unit with precision control and

convenient adjusting device

6. Cooling system to get perfect cooling result

7. Compact structure to save space

8. Prevent bottle from possible pollution by worker

9. Equipped with special designed air storage units

10. Simple installation & startup adjustment

11. Waste rate of finished bottle is less than 0.3%.

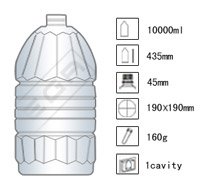

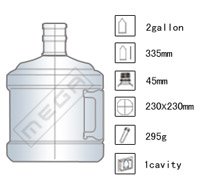

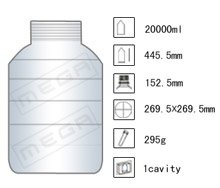

Container/Bottle SamplesFinished PET bottle samples produced by MG-120 as follow:

Edible Oil Bottle

Two gallon water bucket with handle

20L Jar

Three gallon water bucket

Five gallon water bucket

Specification

| General Information | MG-120 |

|---|---|

| Clamping Force | 34T |

| Clamping Stroke | 330mm |

| Max.Stretching Stroke | 550mm |

| Bottom Moving Stroke | 70mm |

| Theoretical Output | 120 BPH |

| Max.Mould Thickness | 400mm |

| Space Between Tie Bars | 520*600mm |

| Electrical System | |

| Voltage Standard | 380v/3PH/50Hz |

| Number of Heating Zone | 2 Sections |

| Total Power(Full Loaded) | 15KW |

| Container | |

| Max.Container Volume | 25L |

| Neck Diameter Range | 65mm |

| Max.Container Diameter | 400mm |

| Max.Container Height | 550mm |

| Auxiliary System | |

| Low Air Compressor | 8-10 Bar |

| High Air Compressor | 30 Bar |

| Air Dryer | 2.0/30 |

| Dimension & Weight (L*W*H) | |

| Blow Molding Machine | 260*190*195cm |

| Pre-heater | |

| Net Weight | 5.2 Ton |

Ywashun machinery, the Professional 5 Gallon Blow Moulding Machine supplier in China.

Note:5 Gallon blow molding machine is also known as Blow Moulding Machine for the large PET bottles, Reheat stretch blow molding machines, Stretch blow molding machines, bottle blowing machine, blowing machines and PET blow molding machine.