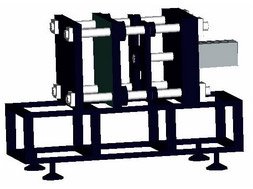

MG-90 PET blow moulding machine for Large PET bottles

Brief Introduction

MG-90 PET blow moulding machine for large PET bottles is

specially designed to produce 5-gallon PET container and 25L

wide mouth jar. Its max output is up to 90 BPH for 5-gallon

bottle and even could reach 120 bottles per hour for the one

way used thin wall 5 gallon bottles.

MG-90 PET blow moulding machine consists of main unit and

rotary infrared heater. The ordinary quartz lamp cannot heat

preform ideally because the preform wall is excessively

thick. The infrared heater with high penetrative force can

heat the inside and outside of preform simultaneously and

keep preform in even heating, therefore high shaping

quality.

OverviewMG-90 PET blow moulding machine consists of two parts: bottle blow unit and preform heater.

* Blow unit

Simple operation and high control

precision

MG bottle blow unit is equipped with

specially designed PLC control system. It

controls the whole bottle production process

through a soft touch pad with time control

precision up to 0.01 second.

* High quality pneumatic

unit

Pneumatic unit provides power for machine

movements including machine driving and

bottle blowing. MG-90 PET blow moulding

machine is equipped with world famous brand

components (Festo, SMC) to reduce the noise,

save energy and produce the high quality

bottles.

* Reliable designed clamping system

with perfect performance

MG-90 adopts three-plate toggle clamping

system to provide powerful clamping force

required by high pressure blowing up to 35

bars. And an adjustment device to change the

distance between front & middle

mold-plate and the position of stretch-seal

cylinder required in different mold

installation.

* Plenty of assistant

units

MG-90 PET stretch blow moulding machine has

a plenty of assistant units to increase the

machine’s performance, such as air storage

unit to keep the air pressure stable,

grease-lubricating unit to reduce mechanical

parts’ wear and tear, and multi-utilization

air entry unit to meet air compressed air

high-pressure single entry mode and

high-pressure & low-pressure double

entry mode.

* Reliable safety unit

In order to keep both machine and operator safe, MG-90

installs twin startup switches on two sides of the machine,

which should be pressed at the same time to start the

machine, while there is also an emergency stop button on

MG-90 to stop machine urgently if necessary.

* Powerful heating

capacity

MG-90 preform heater adopts infrared lamp as

heating unit. Infrared has powerful

thermal-radiation capacity, which can heat

up preform to required temperature in a very

short time, while the strong

thermal-penetrability provides continuous

and uniform heating inside of preform and

over surface of preform.

* Independent heating control

system

MG series preform heater adopts independent

temperature control unit for each heating

zone to offer ideal temperature for various

preforms. Each heating lamp has a voltage

regulator to control the voltage of each

heating lamps and keep it working smoothly.

With the LED display, it becomes easy and

convenient to inspect and adjust the voltage

value.

* Perfect cooling design

MG-90 PET blow moulding machine’s preform heater is equipped

with air-cooling and water-cooling device to remove the

remained heat on preform loader and prevent preform neck

from deformation. And reliable air exhaust system placed on

the heater keeps heating temperature continuous and stable

during preform heating process.

* Multi adjusting device

Multi adjusting device placed on the preform heater

increases the machine’s performance. With those devices, the

heating channel’s width and height can be changed easily

according to the different neck size and neck height. The

mouth of the air exhaust system is also adjustable to meet

different heating requirement.

* Assistant unit for easy operation

For easy operation, MG series preform heater is equipped

with plenty of assistant unit including centralized cooling

water supply system, portable base unit for machine’s

convenient moving, reliable air entry unit and so on, which

makes operation simple and convenient for customer.

Features

1. Special design for PET Gallon Bottle up to 6 Gallon

2. Produce wide mouth jar up to 25 liter with neck size up

to 200mm.

3. Using Infrared reheat units to achieve uniform heating

throughout the wall of preform

4. Adopt special designed preform heating system to ensure

the optimal heating effect for 730g thick-wall preform

5. Special designed fan-cooling system in the heating

channels to keep the oven with constant temperature and

ensure the preform can be heated completely.

6. Water cooling system ensures the quality of preform

neck.

7. Up to 90 bottles/hour using one-cavity mold for 5-gallon

bottle

8. Use advanced PLC control system with counting function

and time-control precision to 0.01second, and a use-friendly

panel.

9. Equipped with special designed air storage units

10.Simple installation & startup adjustment

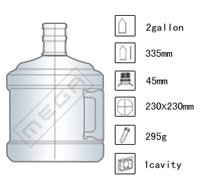

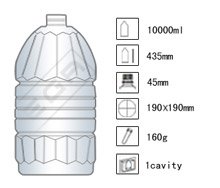

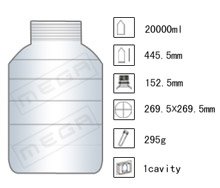

Bottle SamplesFollows are PET bottle samples of MG-90 (picture)

Two gallon

Five gallon

10L jar

Three gallon

20L jar

Technical Parameter

| TYPE | ITEM | UNIT | MG-90 technical data |

|---|---|---|---|

| Container | Product material | / | PET |

| Container volume | L | 5-6 (2-cavity) / 10-25 (1-cavity) | |

| Theoretic output | Psc/hr | 5gallon: 90 / 5L: 400 | |

| Preform length | M | 15-460 | |

| Preform inner diameter | mm | 15-200 | |

| Molding | Max mold thickness | mm | 390 |

| Space Between Tie Bars | mm | 440×550 | |

| Clamping force | T | 30 | |

| Mold opening stroke | mm | 320 | |

| Max.Stretching Stroke | mm | 460 | |

| Main machine electricity | Power | M | 15 |

| Voltage / frequency | V/Hz | 380-240-110/50-60(3 phase) | |

| Machine size and weight | Main machine | M | 2.1×0.82×2.00 |

| Oven | M | 2.52×0.68×1.55 | |

| weight | T | 1.9 | |

Ywashun machinery, the Professional 5 gallon PET Blow Moulding Machine supplier in China.

Note: semi-automatic 5 gallon blow molding machine is also known as Manual blow molding machines for large PET bottle, blow molding machines, bottle blowing machine, blowing machines and PET blow molding machine.