PET Injection Moulding Machines

Brief Introduction

WASHUN has involved with the PET Prefrom molding system since late 80th, According to the experience of the building the preform tools, The PET series Injection molding machine has been designed according to the property of WASHUN’s own preform moulds.WASHUNprovides the different options for our PET machine, such as the additional pressure holding system, the 25:1 PET screw with extended frame base, double pumps system for better plasticizing effect, two stage injection systems for faster cycle time and post cooling system for the preforms.

Features

* PLC Controller

The MG series use the latest control

technology. This high-performance control

system provides the ideal communication

between the injection molding machine and

the operator. The uniform operating concept

and logical, clear structure of the

functions make machine operation easy and

user-oriented.

* PET Injection Unit

Optimized special L/D 25:1 screw, requiring

a longer machine base, is driven by a high

output motor for dramatically improving the

plasticizing of the PET material to ensure

the quality of the PET pre-form. Increased

ejector force consistently ensures the

finished parts are automatically ejected.

* Clamping System

The optuimized kinematics of the proved

5-point toggle represent economical speed

and power processes. This allows high

sensitivity in the opening and closing

processes and protects injection moulds from

excessive wear and tear. The fast mold

closing device is optimized to shorten the

cycle time.

* Automatic Mould Height Adjustment

Unit

Automatic Mould-height adjustment by

hydraulic motor through the gears system

ensures fast and constant settings to

different mold height, achieve platen

parallelism and consistent tonnage. The

photocell detects function to insure the

high precision.

* Hydraulic System

The energy-saving hydraulics are fitted with

sound reduced and are made of high-quality

components. They allow much greater forces

to be transferred and enable very uniform

and precision movements of the machine.

The Models of The PET Injection Molding Machines

| SPECIFICATION | MG-168PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 50 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 353 |

| Injection Weight(PET) | G | 458 |

| Injection Rate | g/s | 170 |

| Plasticizing Capacity | g/d | 25 |

| Injection Pressure | Mpa | 136 |

| Screw Speed | rpm | 0~150 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 1680 |

| Toggle Stroke | mm | 430 |

| Space Between Tie Bars | mm | 460×460 |

| Max. Mold Height | mm | 480 |

| Min. Mold Height | mm | 180 |

| Ejector Stroke | mm | 120 |

| Ejector Tonnage | KN | 40 |

| Ejector Number | Piece | 5 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 15 |

| Heater Power | kw | 13.00 |

| Machine Dimension(LxWxH) | M | 5.3×1.4×2.1 |

| Machine Weight | T | 5.2 |

| Hopper Capacity | kg | 25 |

| Oil Tank Capacity | L | 250 |

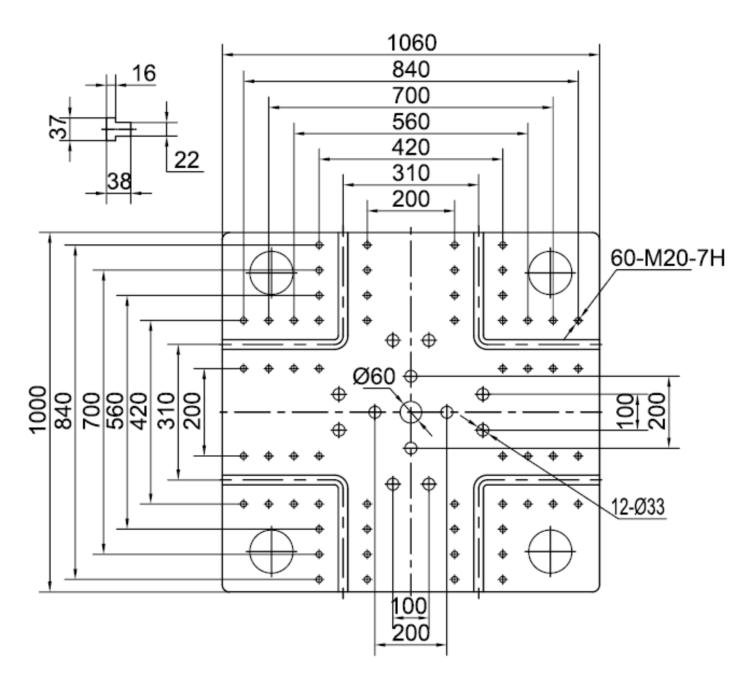

Platen Dimensions Face

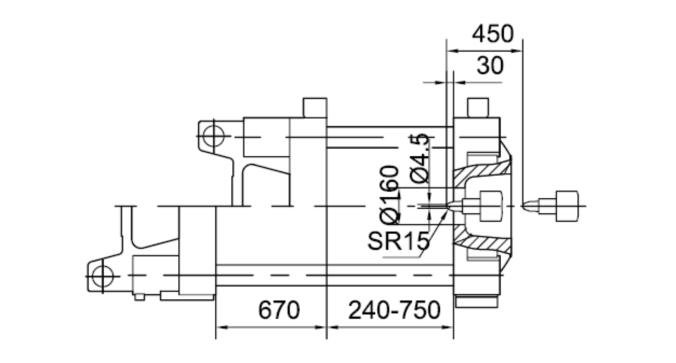

Platen Dimensions Side

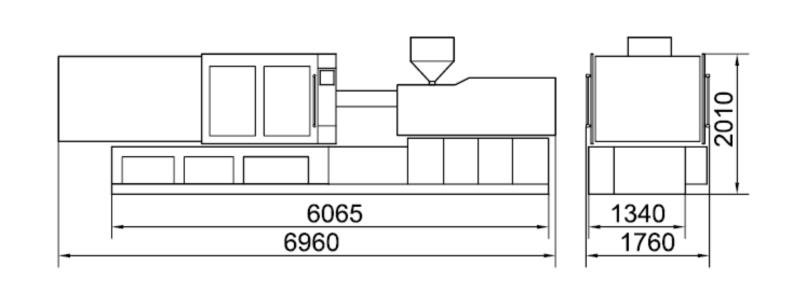

Machine Dimensions

| SPECIFICATION | MG-188PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 52 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 509 |

| Injection Weight(PET) | G | 661 |

| Injection Rate | g/s | 156 |

| Plasticizing Capacity | g/d | 30 |

| Injection Pressure | Mpa | 146 |

| Screw Speed | rpm | 0~195 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 1880 |

| Toggle Stroke | mm | 430 |

| Space Between Tie Bars | mm | 510×460 |

| Max. Mold Height | mm | 530 |

| Min. Mold Height | mm | 180 |

| Ejector Stroke | mm | 140 |

| Ejector Tonnage | KN | 50 |

| Ejector Number | Piece | 5 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 15 |

| Heater Power | kw | 12.8 |

| Machine Dimension(LxWxH) | M | 5.4×1.5×2.1 |

| Machine Weight | T | 5.5 |

| Hopper Capacity | kg | 25 |

| Oil Tank Capacity | L | 280 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-228PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 60 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 636 |

| Injection Weight(PET) | G | 826 |

| Injection Rate | g/s | 273 |

| Plasticizing Capacity | g/d | 49 |

| Injection Pressure | Mpa | 147 |

| Screw Speed | rpm | 0~180 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 2280 |

| Toggle Stroke | mm | 480 |

| Space Between Tie Bars | mm | 510×510 |

| Max. Mold Height | mm | 550 |

| Min. Mold Height | mm | 200 |

| Ejector Stroke | mm | 140 |

| Ejector Tonnage | KN | 65 |

| Ejector Number | Piece | 9 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 22 |

| Heater Power | kw | 15.5 |

| Machine Dimension(LxWxH) | M | 5.7×1.5×2.2 |

| Machine Weight | T | 6.9 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 320 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-268PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 65 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 836 |

| Injection Weight(PET) | G | 1086 |

| Injection Rate | g/s | 334 |

| Plasticizing Capacity | g/d | 52 |

| Injection Pressure | Mpa | 143 |

| Screw Speed | rpm | 0~190 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 2680 |

| Toggle Stroke | mm | 550 |

| Space Between Tie Bars | mm | 570×570 |

| Max. Mold Height | mm | 600 |

| Min. Mold Height | mm | 230 |

| Ejector Stroke | mm | 150 |

| Ejector Tonnage | KN | 65 |

| Ejector Number | Piece | 9 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 30 |

| Heater Power | kw | 17.9 |

| Machine Dimension(LxWxH) | M | 6.4×1.6×2.3 |

| Machine Weight | T | 8.0 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 580 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-288PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 70 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 1058 |

| Injection Weight(PET) | G | 1375 |

| Injection Rate | g/s | 326 |

| Plasticizing Capacity | g/d | 62 |

| Injection Pressure | Mpa | 143 |

| Screw Speed | rpm | 0~190 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 2880 |

| Toggle Stroke | mm | 550 |

| Space Between Tie Bars | mm | 620×570 |

| Max. Mold Height | mm | 640 |

| Min. Mold Height | mm | 230 |

| Ejector Stroke | mm | 190 |

| Ejector Tonnage | KN | 80 |

| Ejector Number | Piece | 9 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 30 |

| Heater Power | kw | 21.2 |

| Machine Dimension(LxWxH) | M | 6.5×1.6×2.3 |

| Machine Weight | T | 9.1 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 580 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-328PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 75 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 1506 |

| Injection Weight(PET) | G | 1957 |

| Injection Rate | g/s | 327 |

| Plasticizing Capacity | g/d | 71 |

| Injection Pressure | Mpa | 137 |

| Screw Speed | rpm | 0~160 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 3280 |

| Toggle Stroke | mm | 670 |

| Space Between Tie Bars | mm | 660×660 |

| Max. Mold Height | mm | 680 |

| Min. Mold Height | mm | 240 |

| Ejector Stroke | mm | 160 |

| Ejector Tonnage | KN | 90 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 37 |

| Heater Power | kw | 21.5 |

| Machine Dimension(LxWxH) | M | 6.9×1.7×2.5 |

| Machine Weight | T | 12.0 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 730 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-368PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 75 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 1635 |

| Injection Weight(PET) | G | 2125 |

| Injection Rate | g/s | 310 |

| Plasticizing Capacity | g/d | 71 |

| Injection Pressure | Mpa | 146 |

| Screw Speed | rpm | 0~160 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 3680 |

| Toggle Stroke | mm | 670 |

| Space Between Tie Bars | mm | 720×660 |

| Max. Mold Height | mm | 750 |

| Min. Mold Height | mm | 240 |

| Ejector Stroke | mm | 180 |

| Ejector Tonnage | KN | 90 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 37 |

| Heater Power | kw | 20.50 |

| Machine Dimension(LxWxH) | M | 7.5×1.85×2.25 |

| Machine Weight | T | 12.8 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 750 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

| SPECIFICATION | MG-398PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 80 |

| Screw L/D Ratio | L/D | 21 |

| Shot Size (Theoretical) | cm3 | 1689 |

| Injection Weight(PET) | G | 2195 |

| Injection Rate | g/s | 446 |

| Plasticizing Capacity | g/d | 70 |

| Injection Pressure | Mpa | 152 |

| Screw Speed | rpm | 0~165 |

| CLAMPING UNIT | ||

|---|---|---|

| Clamp Tonnage | KN | 3980 |

| Toggle Stroke | mm | 700 |

| Space Between Tie Bars | mm | 720×720 |

| Max. Mold Height | mm | 800 |

| Min. Mold Height | mm | 280 |

| Ejector Stroke | mm | 160 |

| Ejector Tonnage | KN | 110 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

|---|---|---|

| Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kW | 37 |

| Heater Power | kW | 26.2 |

| Machine Dimension(LxWxH) | M | 7.3×1.9×2.5 |

| Machine Weight | T | 15.7 |

| Hopper Capacity | L | 50 |

| Oil Tank Capacity | L | 750 |

Platen Dimensions Face

Platen Dimensions Side

Machine Dimensions

Ywashun machinery, the Professional PET Injection moulding machine supplier in China.

Note: PET Injection moulding machine is also known as PET Injection molding machines, plastic molding machines machines and plastic Injection moulding machine.